Hallo!

Just getting some double and triple mileage out of this post...

And now for something completely different....

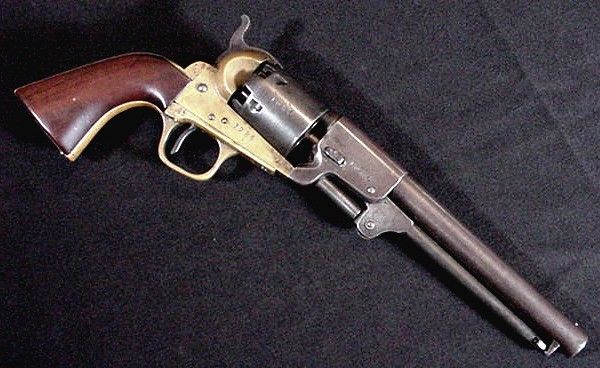

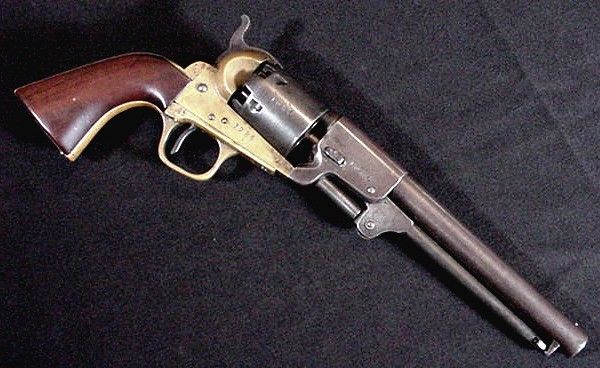

Let's "dissect" a Griswold & Gunnison Revolver, aka Griswold & Grier, aka Griswold & Geer, aka Griswoldville Revolver..

Former Connecticuter Samuel Griswold had made a small fortune making cotton gins before the Civil War in Georgia...eventually using 100 slaves in the factory. As well as a small community around it, called Griswoldville about 12 miles outside of Macon.

When the War broke out in 1861, he made "Georgia pikes" of all things. (Never bring a pike to a gunfight...)

His business partner was Arvin Gunnison, a New Englander who had gone South to teach school in Georgia, and when the War started was making cotton gins in New Orleans. When New Orleans fell, he went to Georgia and joined up with Griswold. Some accounts say Gunnison was operating a gun shop in New Orleans.

Fearful the Savannah would fall to the Federals from the sea in the Spring of 1862, Colonel Gorgas, Chief of Confederate Ordnance, had decided to move CS ordnance stores from Savannah 180 some miles inland to Macon. But the problem was that there were no government facilities there. Captain Richard Cuyler, in charge of C.S. Ordnance at Savannah, went to Macon and scouted it out, purchasing the old Finlay Iron Works and converting it into the a C.S. Arsenal.

He also took over the business of D.C. Hodgkins & Sons, a local gunmaker family.

Cuyler went about looking for possible arms makers, and had a look at Griswold'a capabilities.

In April or May of 1862, smelling a financial opportunity, Griswold came up with a clone of the Colt M1851 Navy revolver (well actually a smaller version of a Colt 3rd Model Dragoon), and made up protype(s) for Gorgas. Colonel (later General) Gorgas was impressed. So much so, he tolds Griswold that he would take as many as Griswold could make at $40 each providing they passed inspection.

Sam Griswold set up production, settinn up 24 machines manned by 22 slaves. The work proved to be more than the slaves could handle, and Captain Cuyler intervened teaching things lile how to case harden, temper springs, or polish metal. Still somewhat skeptical, Cuyler said it would take skilled "practical mechanics" to assemble and time the revolvers which should all be subject to inspection AND proofing.

Griswold was up and runnng, with a view to use the 24 machines to turn out 50-60 revolvers a week.

And Cuyler had them proofed- first with 55 grains of rifle powder, two round balls, and two wads. Second with 82 grain charges, and two conical bullets. Not so good, they burst. The iron was thought to be too weak. Cuyler then recommend the British proofing system of 120 grains Provisional, and 75 grains Definitive.

Not having steel enough, G & G went with the iron cylinders, but twisted the iron for added strength. You can often see the twist lines in the cylinders.

Hodgkins set about to proof three barrels. First proof was 465 grains with two wads and two balls. The second, with 232.

And finally a range from 55 to 165 grains (him saying the charge and two balls almost filled the barrel entirely) Believing it impossible to burst either of the above by fair means, we deemed the above sufficient."

Griswold was in business. cranking out 100 between July and October 1862.

Three were inspected and proofed with what was felt to be a maximiun possible field charge- filling the chambers nearly full with powder, some with one bullet, some with two. All three barrels burst. A fourth had a broken hand spring. A fifth had a busted tube (nipple/cone). A sixth had a broken ramrod catch. The last three were returned for minor repairs and resubmission.

Griswoldville was located along a railroad line making supplying it easy. BUT breakdowns in available supplies such as iron, coal, or coke hampered production.

But WORST of all was brass. (Now) Lt. Colonel Cuyler asked for permission to go to the local population to "loan" the government their brass or bronze church bells. So soon bells were arriving to be smelted down for cannon, sword hilts, and revolver frames. (So, G & G's had yellow brass or red brass frames depending upon the copper content of the bronze bells on hand at the moment..)

Average production for Griswold between October 1862 and November 1864 was about 100 revolvers a month, first at $40 each, then at $50.

On November 1, 1864 Sherman occupied Atlanta. Cleverly fearing what was coming, Griswold wrote to Colonel Burton at the Macon Armory that he thought it to no good purpose to continue to own the Griswoldville gun works. He prefered that the C.S. Government either rent or buy them. Burton opposed it, and instead suggested that Griswold be paid more as an incentive to keep going.

On November 11th, Sherman began his "march" from "Atlanta to the Sea." In a fruitless attempt to stop him, on November 22, 1864 General Joe Wheeler's cavalry and a force made up largely of old men and boys in the home guard and militia met the experienced Yankees on a hill about a mile outside of Griswoldville (Griswoldville Station). Unable to even slow down the Yankee juggernaut, the 10th Ohio Cavalry and/or 3rd Union Kentucky cavalry took Griswold's pistol factory and burned it.

Total production, based on a serial number of 3,500 is guestimated at 3,700. which is impressive, as IIRC, that is roughly the sum total of all other revolver makers combined.

Because the assembly line would not be "invented" by Henry Ford for a few decades... production of arms was piecework, meaning pieces and parts were worked on at different times, and the same workers did not work continously (in a straight line) until the guns were complete.) Once enough pieces/parts were on hand, workers were formed into squads or teams. One man was plapce din charged and was repsonsible for the guns his team was workiong on. Parts and sub-assemblies were stamped or marked so the workers knew what fitted where when.

After they were completely finished their three principle sub groupings were with aportion of the serial number. SErial numbers too large to fit, were abbreviatred by using the last two digits.

After the gun was completed, it was disassembled and each part was inspected by the foreman. The foreman then pplaced his stamp or "cryptic" mark identifying him upon each major part.

G & G's often turn up as fakes or counterfeits. But the Italian repros have the wrong barrel twist and grooves, and wrong screws. They are smaller and lighter in weight than originals. The barrel lug is different, as is the barel wedge. They are not correctly marked or stamped... especially with the myriad of production and sub-assemby pieces/part markings. The angle of the bottom of the grip and grip frame is off.

They also are made of better materials such as hard steel, and actually, believe it or not, have more exacting tolerances than do the originals.

Curt

Just getting some double and triple mileage out of this post...

And now for something completely different....

Let's "dissect" a Griswold & Gunnison Revolver, aka Griswold & Grier, aka Griswold & Geer, aka Griswoldville Revolver..

Former Connecticuter Samuel Griswold had made a small fortune making cotton gins before the Civil War in Georgia...eventually using 100 slaves in the factory. As well as a small community around it, called Griswoldville about 12 miles outside of Macon.

When the War broke out in 1861, he made "Georgia pikes" of all things. (Never bring a pike to a gunfight...)

His business partner was Arvin Gunnison, a New Englander who had gone South to teach school in Georgia, and when the War started was making cotton gins in New Orleans. When New Orleans fell, he went to Georgia and joined up with Griswold. Some accounts say Gunnison was operating a gun shop in New Orleans.

Fearful the Savannah would fall to the Federals from the sea in the Spring of 1862, Colonel Gorgas, Chief of Confederate Ordnance, had decided to move CS ordnance stores from Savannah 180 some miles inland to Macon. But the problem was that there were no government facilities there. Captain Richard Cuyler, in charge of C.S. Ordnance at Savannah, went to Macon and scouted it out, purchasing the old Finlay Iron Works and converting it into the a C.S. Arsenal.

He also took over the business of D.C. Hodgkins & Sons, a local gunmaker family.

Cuyler went about looking for possible arms makers, and had a look at Griswold'a capabilities.

In April or May of 1862, smelling a financial opportunity, Griswold came up with a clone of the Colt M1851 Navy revolver (well actually a smaller version of a Colt 3rd Model Dragoon), and made up protype(s) for Gorgas. Colonel (later General) Gorgas was impressed. So much so, he tolds Griswold that he would take as many as Griswold could make at $40 each providing they passed inspection.

Sam Griswold set up production, settinn up 24 machines manned by 22 slaves. The work proved to be more than the slaves could handle, and Captain Cuyler intervened teaching things lile how to case harden, temper springs, or polish metal. Still somewhat skeptical, Cuyler said it would take skilled "practical mechanics" to assemble and time the revolvers which should all be subject to inspection AND proofing.

Griswold was up and runnng, with a view to use the 24 machines to turn out 50-60 revolvers a week.

And Cuyler had them proofed- first with 55 grains of rifle powder, two round balls, and two wads. Second with 82 grain charges, and two conical bullets. Not so good, they burst. The iron was thought to be too weak. Cuyler then recommend the British proofing system of 120 grains Provisional, and 75 grains Definitive.

Not having steel enough, G & G went with the iron cylinders, but twisted the iron for added strength. You can often see the twist lines in the cylinders.

Hodgkins set about to proof three barrels. First proof was 465 grains with two wads and two balls. The second, with 232.

And finally a range from 55 to 165 grains (him saying the charge and two balls almost filled the barrel entirely) Believing it impossible to burst either of the above by fair means, we deemed the above sufficient."

Griswold was in business. cranking out 100 between July and October 1862.

Three were inspected and proofed with what was felt to be a maximiun possible field charge- filling the chambers nearly full with powder, some with one bullet, some with two. All three barrels burst. A fourth had a broken hand spring. A fifth had a busted tube (nipple/cone). A sixth had a broken ramrod catch. The last three were returned for minor repairs and resubmission.

Griswoldville was located along a railroad line making supplying it easy. BUT breakdowns in available supplies such as iron, coal, or coke hampered production.

But WORST of all was brass. (Now) Lt. Colonel Cuyler asked for permission to go to the local population to "loan" the government their brass or bronze church bells. So soon bells were arriving to be smelted down for cannon, sword hilts, and revolver frames. (So, G & G's had yellow brass or red brass frames depending upon the copper content of the bronze bells on hand at the moment..)

Average production for Griswold between October 1862 and November 1864 was about 100 revolvers a month, first at $40 each, then at $50.

On November 1, 1864 Sherman occupied Atlanta. Cleverly fearing what was coming, Griswold wrote to Colonel Burton at the Macon Armory that he thought it to no good purpose to continue to own the Griswoldville gun works. He prefered that the C.S. Government either rent or buy them. Burton opposed it, and instead suggested that Griswold be paid more as an incentive to keep going.

On November 11th, Sherman began his "march" from "Atlanta to the Sea." In a fruitless attempt to stop him, on November 22, 1864 General Joe Wheeler's cavalry and a force made up largely of old men and boys in the home guard and militia met the experienced Yankees on a hill about a mile outside of Griswoldville (Griswoldville Station). Unable to even slow down the Yankee juggernaut, the 10th Ohio Cavalry and/or 3rd Union Kentucky cavalry took Griswold's pistol factory and burned it.

Total production, based on a serial number of 3,500 is guestimated at 3,700. which is impressive, as IIRC, that is roughly the sum total of all other revolver makers combined.

Because the assembly line would not be "invented" by Henry Ford for a few decades... production of arms was piecework, meaning pieces and parts were worked on at different times, and the same workers did not work continously (in a straight line) until the guns were complete.) Once enough pieces/parts were on hand, workers were formed into squads or teams. One man was plapce din charged and was repsonsible for the guns his team was workiong on. Parts and sub-assemblies were stamped or marked so the workers knew what fitted where when.

After they were completely finished their three principle sub groupings were with aportion of the serial number. SErial numbers too large to fit, were abbreviatred by using the last two digits.

After the gun was completed, it was disassembled and each part was inspected by the foreman. The foreman then pplaced his stamp or "cryptic" mark identifying him upon each major part.

G & G's often turn up as fakes or counterfeits. But the Italian repros have the wrong barrel twist and grooves, and wrong screws. They are smaller and lighter in weight than originals. The barrel lug is different, as is the barel wedge. They are not correctly marked or stamped... especially with the myriad of production and sub-assemby pieces/part markings. The angle of the bottom of the grip and grip frame is off.

They also are made of better materials such as hard steel, and actually, believe it or not, have more exacting tolerances than do the originals.

Curt

Comment